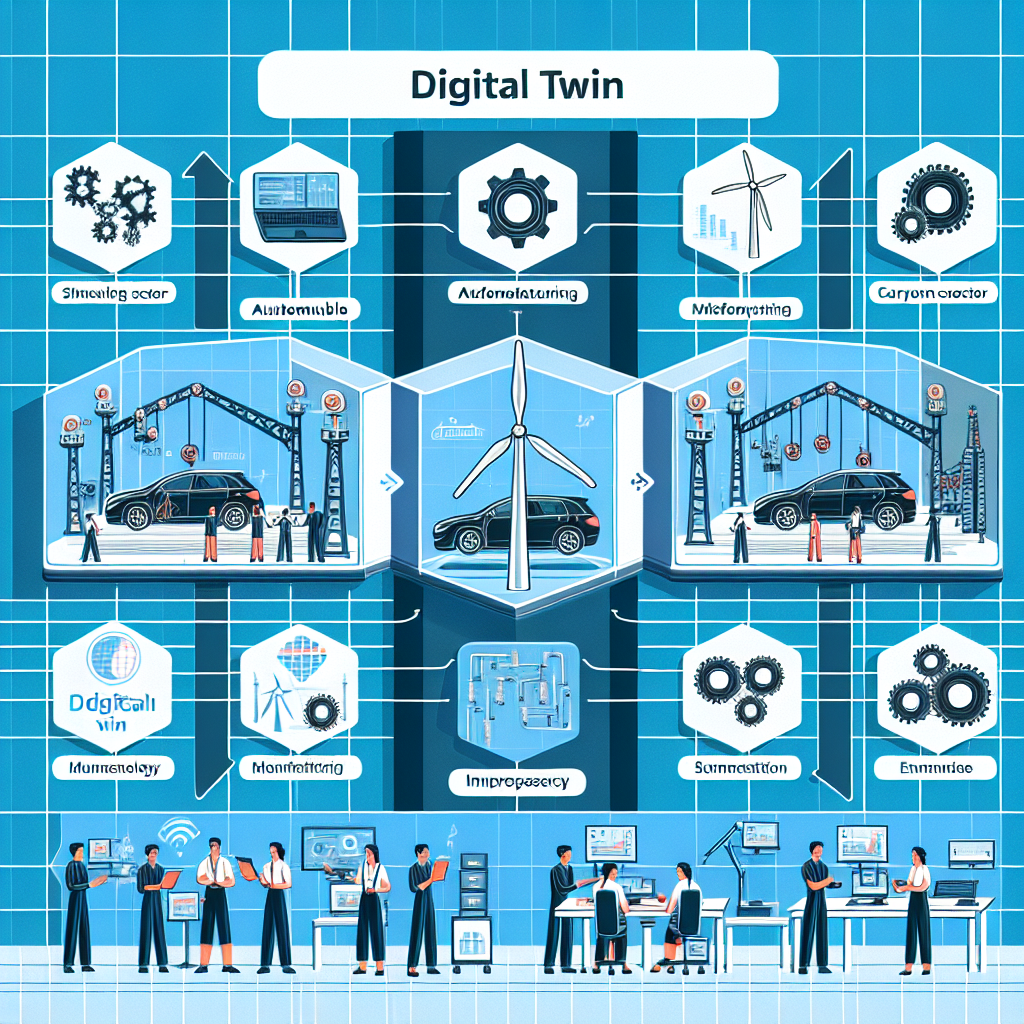

Digital twins are virtual models that replicate physical objects or systems, providing a real-time simulation of their behavior. This technology has been gaining popularity in various industries due to its ability to improve efficiency, reduce costs, and enhance decision-making processes. Let’s take a look at some case studies showcasing successful implementations of digital twins in different sectors.

Industrial Simulation

One industry that has greatly benefited from digital twins is manufacturing. By creating virtual replicas of production lines and equipment, manufacturers can simulate different scenarios and optimize their operations. For example, a leading automotive company used digital twins to identify bottlenecks in their assembly line and improve overall efficiency by 15%.

Tech Integration

Another area where digital twins have proven to be valuable is in the integration of new technologies. A major oil and gas company implemented digital twins to monitor the performance of their offshore platforms and predict maintenance needs. By combining data from sensors with advanced analytics, they were able to reduce downtime and increase productivity.

Conclusion

These case studies demonstrate the power of digital twins in revolutionizing industries through virtual models and industrial simulation. As technology continues to advance, we can expect even more innovative applications of this technology across various sectors. Whether it’s optimizing manufacturing processes or improving asset management, digital twins offer endless possibilities for businesses looking to stay ahead in today’s competitive landscape.

Leave a Reply